Kangtao

Building material

ISO9001

GB/T700 Q235A Q235B ASTM A283M Gr.D JIS

Galvanizing, painting, phosphating and bright annealing, etc.

1000-2500MM Or Customize

customized

carbon steel coil

ASTM A36, ASTM A572, JIS G3101, GB/T 700, etc

Hot Rolled

Q235B

customized

| Availability: | |

|---|---|

| Quantity: | |

| Product Name: | Carbon Steel Coil | ||

| Thickness Range: | 0.5mm - 20mm | Tensile Strength: | 400 - 550 MPa |

| Width Range: | 600mm - 2500mm | Yield Strength: | ≥ 245 MPa |

| Roll Weight: | 1 - 20 Ton | Elongation Rate: | ≥ 20% |

| Main grade: | St37/St52/SS400/A36/Q235B/Q345A/Q345B/A516GR60/A516GR70/AH32/AH36 | ||

| Material: | NM450L,NM450A,NM600,NM400,NM400L,NM400A,NM500A,NM500,NM360L,NM360;Q345,Q345A,,Q345B,Q345C,Q345D,Q345E,Q235B, HC340LA,HC380LA,HC420LA,B340LA,B410LA;09CuPCrNi-A,09CuP, 09CuPCrNiA, 09CrCuSb Q355NH,Q460NH,Q345GNHL,Q345GNHL,Q355GNH,Q345GNH; | ||

| Standard: | ASTM A36, ASTM A572, JIS G3101, GB/T 700, etc | ||

| Surface: | Galvanizing, painting, phosphating and bright annealing, etc. | ||

Carbon steel coils have high strength, can withstand great pressure and heavy loads, and perform well in projects that require long-term durability, especially suitable for use as load-bearing components in building structures and mechanical equipment. Carbon steel coils have strong plasticity and are suitable for various processing techniques, including cold rolling, hot rolling, stamping, cutting, welding, and bending. It is easy to form complex shapes and sizes, and can quickly complete large-scale production

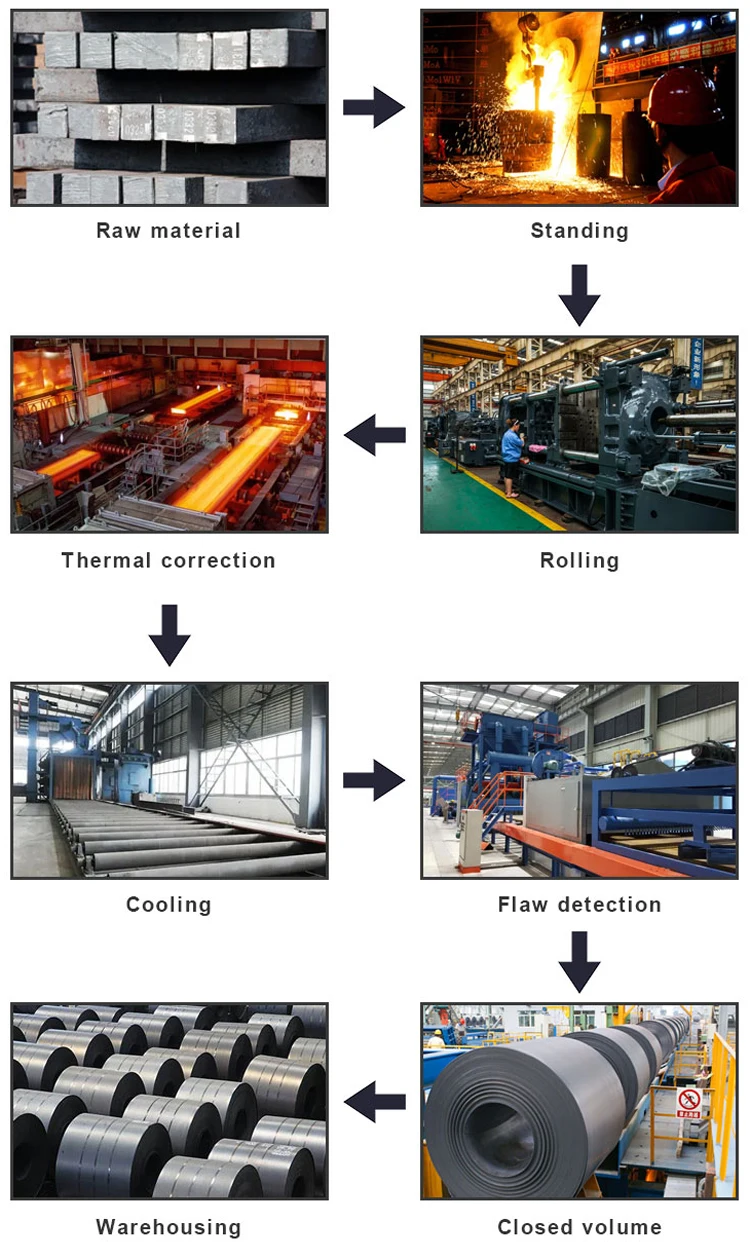

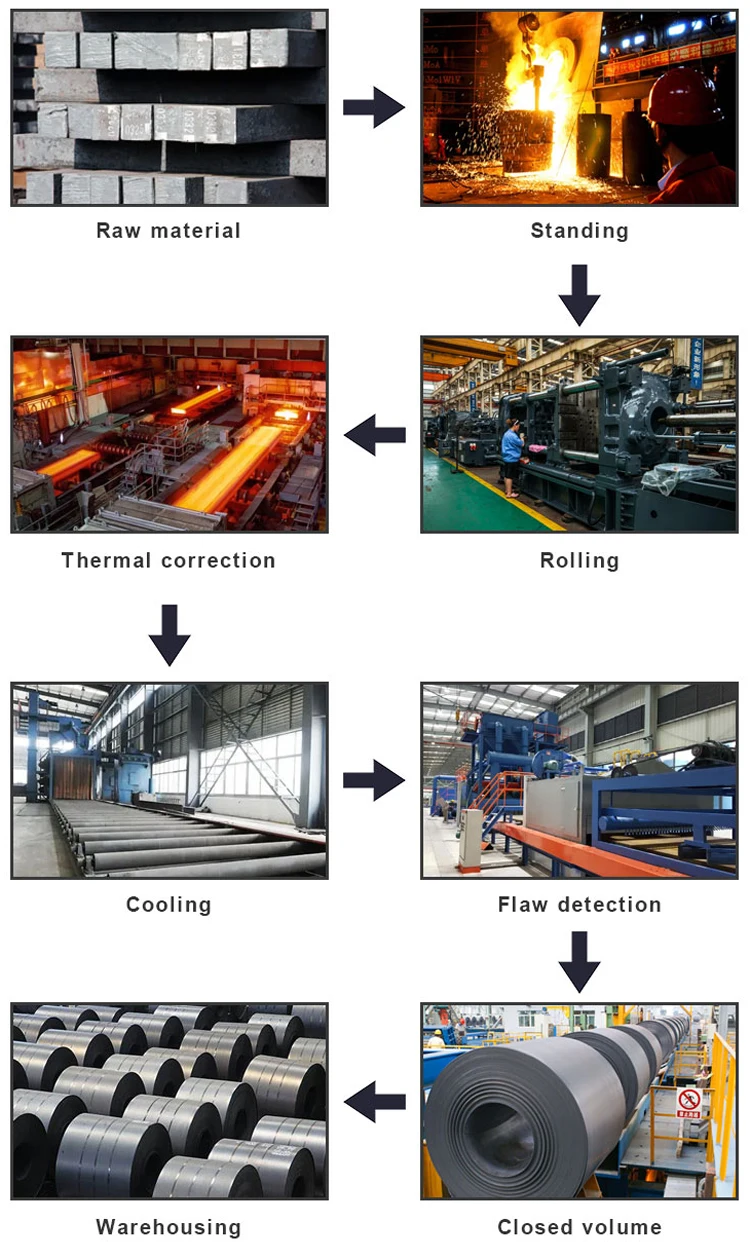

Product Process

1.How to deal with oxide scale on carbon steel coils?

Oxidation scale often appears on the surface of hot-rolled carbon steel coils, which can usually be removed by acid washing, mechanical polishing, or sandblasting. If a smoother surface is required, cold-rolled carbon steel coils can be chosen.

2.What is the yield strength of carbon steel coil?

The yield strength of carbon steel coils varies depending on the material. Generally speaking, the yield strength of low-carbon steel is lower, while the yield strength of medium carbon steel and high carbon steel is higher. The specific yield strength can be queried based on the material grade and standard.

3.What is the ductility of carbon steel coils?

The ductility of carbon steel coils depends on their carbon content. Low carbon steel coils have good ductility and are suitable for stretching and forming processing; High carbon steel coils have lower ductility but higher strength, making them suitable for manufacturing high-strength structural components.

4.Is carbon steel coil suitable for high temperature environments?Carbon steel coils can be used in certain high-temperature environments, but if the temperature is too high, it may affect their strength and durability. For high-temperature working environments, it is recommended to choose specially designed heat-resistant steel coils.

5.Can carbon steel coils undergo secondary processing?Yes, carbon steel coils can undergo secondary processing through cutting, stamping, bending, welding, and other processes. Carbon steel materials have good processing properties and are suitable for various manufacturing processes.

| Product Name: | Carbon Steel Coil | ||

| Thickness Range: | 0.5mm - 20mm | Tensile Strength: | 400 - 550 MPa |

| Width Range: | 600mm - 2500mm | Yield Strength: | ≥ 245 MPa |

| Roll Weight: | 1 - 20 Ton | Elongation Rate: | ≥ 20% |

| Main grade: | St37/St52/SS400/A36/Q235B/Q345A/Q345B/A516GR60/A516GR70/AH32/AH36 | ||

| Material: | NM450L,NM450A,NM600,NM400,NM400L,NM400A,NM500A,NM500,NM360L,NM360;Q345,Q345A,,Q345B,Q345C,Q345D,Q345E,Q235B, HC340LA,HC380LA,HC420LA,B340LA,B410LA;09CuPCrNi-A,09CuP, 09CuPCrNiA, 09CrCuSb Q355NH,Q460NH,Q345GNHL,Q345GNHL,Q355GNH,Q345GNH; | ||

| Standard: | ASTM A36, ASTM A572, JIS G3101, GB/T 700, etc | ||

| Surface: | Galvanizing, painting, phosphating and bright annealing, etc. | ||

Carbon steel coils have high strength, can withstand great pressure and heavy loads, and perform well in projects that require long-term durability, especially suitable for use as load-bearing components in building structures and mechanical equipment. Carbon steel coils have strong plasticity and are suitable for various processing techniques, including cold rolling, hot rolling, stamping, cutting, welding, and bending. It is easy to form complex shapes and sizes, and can quickly complete large-scale production

Product Process

1.How to deal with oxide scale on carbon steel coils?

Oxidation scale often appears on the surface of hot-rolled carbon steel coils, which can usually be removed by acid washing, mechanical polishing, or sandblasting. If a smoother surface is required, cold-rolled carbon steel coils can be chosen.

2.What is the yield strength of carbon steel coil?

The yield strength of carbon steel coils varies depending on the material. Generally speaking, the yield strength of low-carbon steel is lower, while the yield strength of medium carbon steel and high carbon steel is higher. The specific yield strength can be queried based on the material grade and standard.

3.What is the ductility of carbon steel coils?

The ductility of carbon steel coils depends on their carbon content. Low carbon steel coils have good ductility and are suitable for stretching and forming processing; High carbon steel coils have lower ductility but higher strength, making them suitable for manufacturing high-strength structural components.

4.Is carbon steel coil suitable for high temperature environments?Carbon steel coils can be used in certain high-temperature environments, but if the temperature is too high, it may affect their strength and durability. For high-temperature working environments, it is recommended to choose specially designed heat-resistant steel coils.

5.Can carbon steel coils undergo secondary processing?Yes, carbon steel coils can undergo secondary processing through cutting, stamping, bending, welding, and other processes. Carbon steel materials have good processing properties and are suitable for various manufacturing processes.