Kangtao

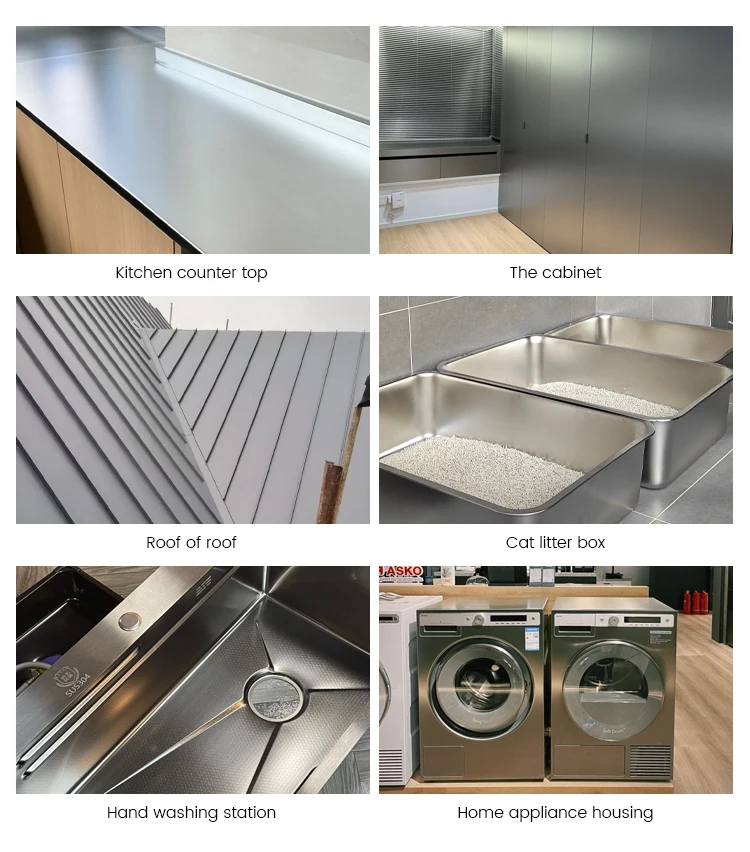

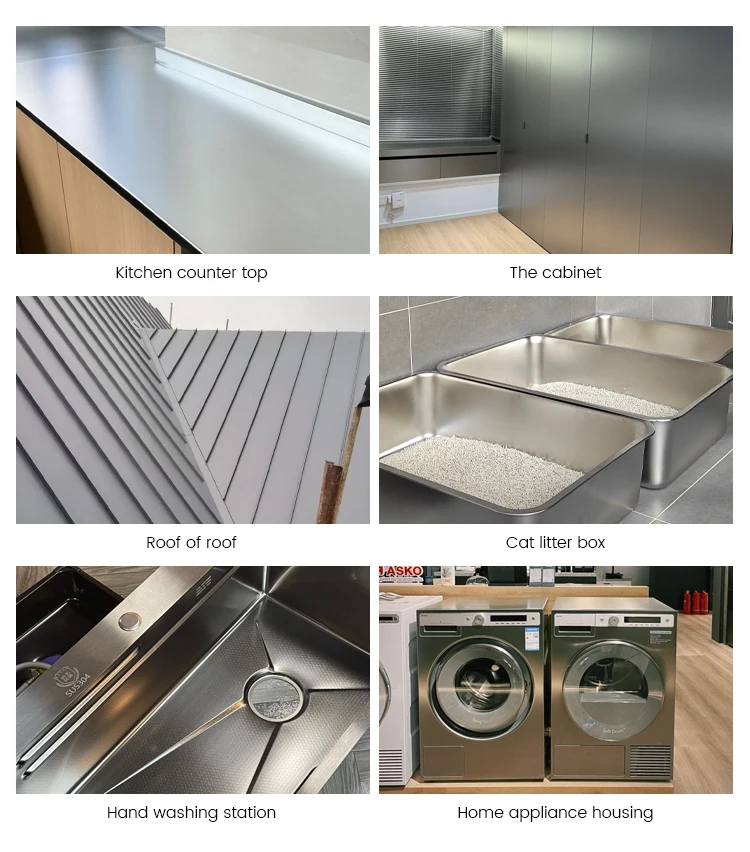

Construction field, ships building industry, petroleum,chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.

RoHS, ISO9001, ASTM, JIS, GB, EN, ASTMB

310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex etc

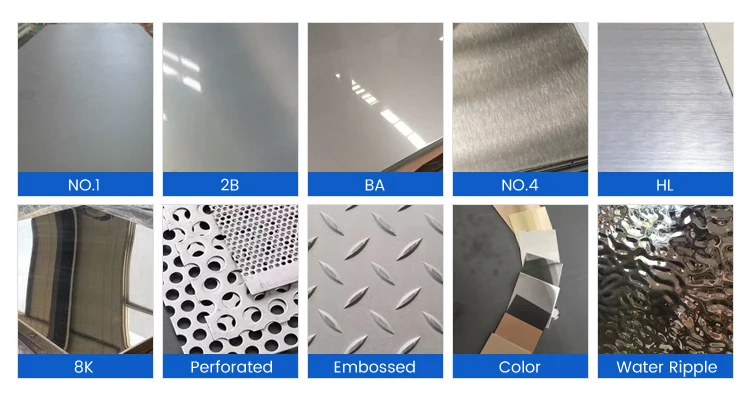

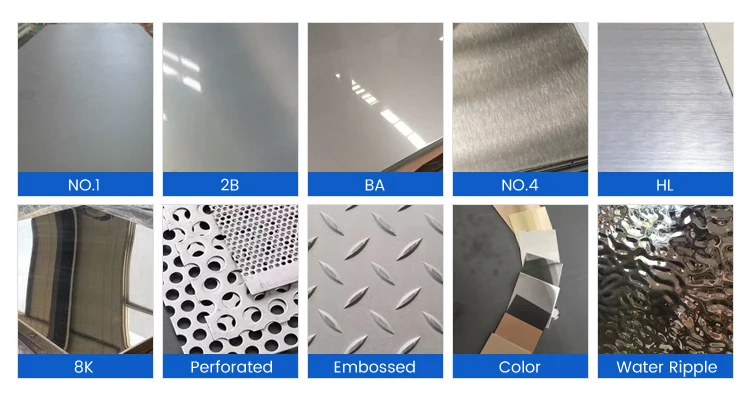

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching etc

0.2~200mm

0.1-120mm

stainless steel coil

ASTM A240, GB/T3280-2007, JIS4304-2005, ASTM A167, EN10088-2-2005 etc

Hot Rolled Cold Rolled

100-12000mm

| Availability: | |

|---|---|

| Quantity: | |

| Product Name | Stainless Steel Sheet |

| Grade | 310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex etc |

| Standard | ASTM A240, GB/T3280-2007, JIS4304-2005, ASTM A167, EN10088-2-2005 etc |

| Surface Treatment | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching etc |

| Technique | Hot rolled & Cold rolled |

| Application | Construction field, ships building industry, petroleum,chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Features | Corrosion resistance, high strength and toughness, aesthetics, easy processing, heat resistance, environmental protection |

| Width | 0.2~200mm |

| Length | 100-12000mm |

| Thickness | 0.1-120mm |

| Tolerance | ±1 |

| Package | Standard export package, suit for all kinds of transport or as required. |

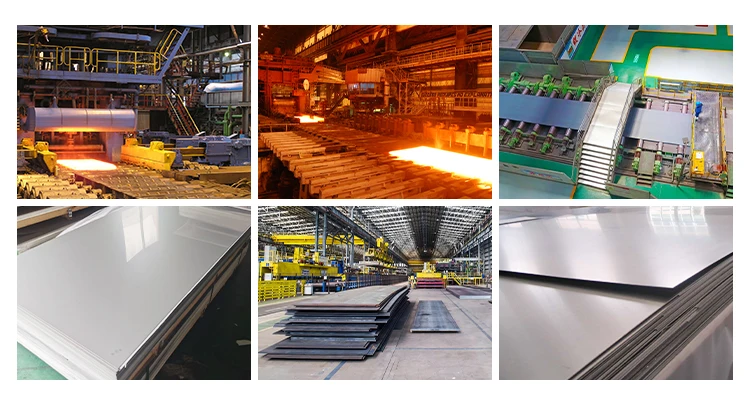

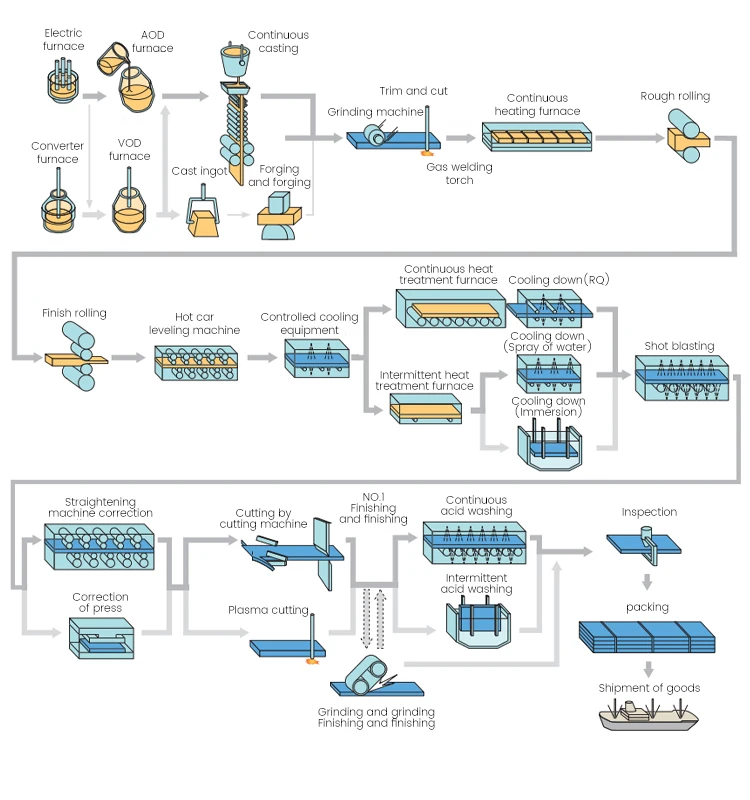

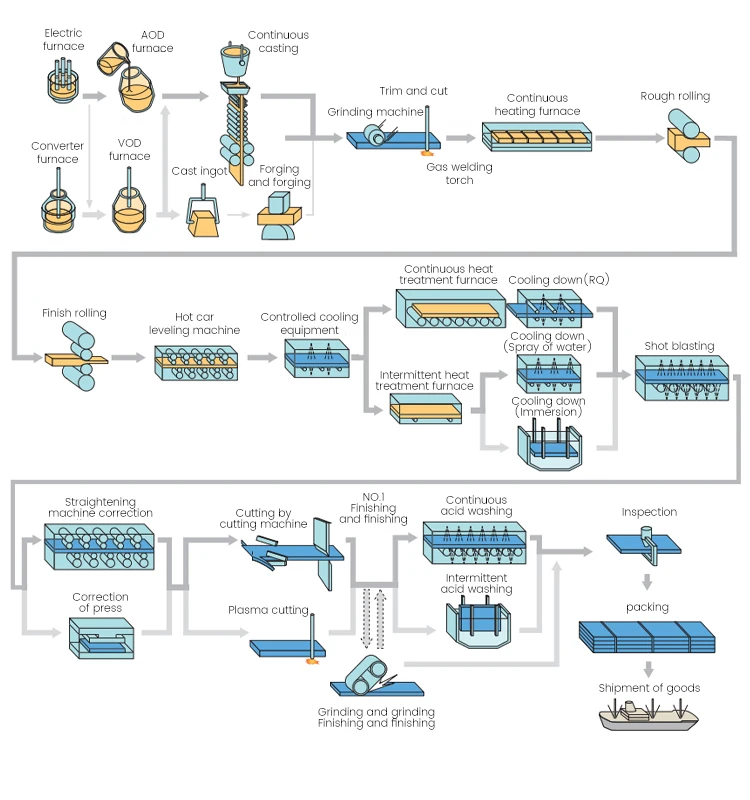

1. Raw material preparation and smeltingMaterial selection: mainly use stainless steel scrap, iron ore and alloying elements (such as chromium, nickel, molybdenum, etc.) to ensure that the chemical composition of the material meets the standard.Smelting: Heating raw materials to liquid form molten steel in an electric arc furnace (EAF). In this process, FeCr, Ni and other alloys may be added to adjust the composition.To refine: Decarbonization: Remove excess carbon and other impurities through AOD (argon oxygen decarbonization furnace) or VOD (vacuum oxygen decarbonization furnace) to improve the purity of molten steel.Secondary refining: The composition is further adjusted in LF (ladle refining furnace) to ensure the quality of molten steel.

2. Casting and primary processingContinuous casting (CC) : The continuous casting of refined molten steel into slabs or billets to form an initial solid shape.Billet heating: the continuous casting billet is heated to 1100 -- 1250℃ to facilitate subsequent rolling at a uniform temperature.

3. Rolling processHot rolling - descaling: The oxide layer on the surface of the billet is removed by high-pressure water. Rough rolling and finishing rolling: the heated blank is rolled through multiple passes and gradually thinned to the target thickness to form a hot rolling coil.Annealing: After hot rolling, the sheet is annealed (heated to a specific temperature and then cooled slowly) to eliminate internal stress and improve ductility.Pickling: use nitric acid-hydrofluoric acid mixture to remove the oxide scale produced by annealing, so that the surface is smooth and clean.Cold rolling: hot rolled pickling coils are further rolled at room temperature to obtain thinner (e.g. 0.3mm or less) cold rolled plates with higher flatness.

4. Surface treatment and post-processingPolishing/Drawing: Mechanical polishing or electrolytic polishing to improve surface finish, or drawing process to form texture.Slaying and molding: Cutting, bending, or welding the sheet into the final product shape as required. Plating/coating: some products need to be tinned, chromified or sprayed with anti-rust paint to enhance corrosion resistance.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

| Product Name | Stainless Steel Sheet |

| Grade | 310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex etc |

| Standard | ASTM A240, GB/T3280-2007, JIS4304-2005, ASTM A167, EN10088-2-2005 etc |

| Surface Treatment | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching etc |

| Technique | Hot rolled & Cold rolled |

| Application | Construction field, ships building industry, petroleum,chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Features | Corrosion resistance, high strength and toughness, aesthetics, easy processing, heat resistance, environmental protection |

| Width | 0.2~200mm |

| Length | 100-12000mm |

| Thickness | 0.1-120mm |

| Tolerance | ±1 |

| Package | Standard export package, suit for all kinds of transport or as required. |

1. Raw material preparation and smeltingMaterial selection: mainly use stainless steel scrap, iron ore and alloying elements (such as chromium, nickel, molybdenum, etc.) to ensure that the chemical composition of the material meets the standard.Smelting: Heating raw materials to liquid form molten steel in an electric arc furnace (EAF). In this process, FeCr, Ni and other alloys may be added to adjust the composition.To refine: Decarbonization: Remove excess carbon and other impurities through AOD (argon oxygen decarbonization furnace) or VOD (vacuum oxygen decarbonization furnace) to improve the purity of molten steel.Secondary refining: The composition is further adjusted in LF (ladle refining furnace) to ensure the quality of molten steel.

2. Casting and primary processingContinuous casting (CC) : The continuous casting of refined molten steel into slabs or billets to form an initial solid shape.Billet heating: the continuous casting billet is heated to 1100 -- 1250℃ to facilitate subsequent rolling at a uniform temperature.

3. Rolling processHot rolling - descaling: The oxide layer on the surface of the billet is removed by high-pressure water. Rough rolling and finishing rolling: the heated blank is rolled through multiple passes and gradually thinned to the target thickness to form a hot rolling coil.Annealing: After hot rolling, the sheet is annealed (heated to a specific temperature and then cooled slowly) to eliminate internal stress and improve ductility.Pickling: use nitric acid-hydrofluoric acid mixture to remove the oxide scale produced by annealing, so that the surface is smooth and clean.Cold rolling: hot rolled pickling coils are further rolled at room temperature to obtain thinner (e.g. 0.3mm or less) cold rolled plates with higher flatness.

4. Surface treatment and post-processingPolishing/Drawing: Mechanical polishing or electrolytic polishing to improve surface finish, or drawing process to form texture.Slaying and molding: Cutting, bending, or welding the sheet into the final product shape as required. Plating/coating: some products need to be tinned, chromified or sprayed with anti-rust paint to enhance corrosion resistance.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade

company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.